Precast concrete production

PRECAST CONCRETE PRODUCTION

Producers of precast concrete elements use large quantities of concrete. The most impactful parameter of the industry is its carbon footprint. Concrete is a building material composed of cement, water and the aggregates sand, gravel and/or crushed stone.

According to researchers, the production of cement emits a huge amount of CO2: about 8 per cent of all CO2 emissions worldwide. This means that not using concrete effectively is not only a waste of materials and costs, but also causes unnecessary damage to the environment. It is therefore very important to prevent residual concrete in the production process of precast concrete units.

Residual concrete is produced during the production of wide (floor) slabs, concrete beams, concrete columns and concrete walls. During quality checks of the produced concrete, for example, it may be discovered that the mixture is not good enough for the production of concrete elements after all. A production error may have been made. But the residue can also just be leftover concrete that cannot be used in the elements to be produced.

Disposing of residual concrete is irresponsible, and also unnecessary. Near factories, residual concrete is often allowed to harden in a landfill. The cured concrete is then crushed and sieved in a crushing plant, after which the resulting aggregate is used to produce new concrete products.

The aggregate may also be used for other applications. The process of crushing (reducing) and screening residual concrete consumes a lot of energy. Recycling hardened concrete into concrete rubble aggregates is unnecessary.

SMARTER AND MORE CIRCULAR PROCESSING OF RESIDUAL CONCRETE

A truly circular and smart solution is to use residual concrete for an end product that can be made when ready-mix concrete still has a good viscosity and the curing process has not yet started. Using quality ready mixed concrete for production of concrete aggregates is nonsensical, and is also known as downcycling.

Recycling fresh in-situ concrete by washing it out so that the aggregates and sludge water can be reused requires high energy consumption and is a costly recycling process. The water consumption of the production process and the recycling process is immense.

The production of stackable concrete blocks is the perfect solution for the immediate responsible disposal of fresh, uncured residual concrete. Stackable concrete blocks are like oversized building bricks: standardized block-shaped modules built in a concrete plant. A building system with dimensionally stable concrete blocks that needs no filler or other fasteners.

Who did not used to play with building blocks to make countless creative structures? The large concrete blocks are like giant building bricks for adults. The concrete blocks can be used in numerous ways, such as to make retaining walls, manure silos, storage bunkers, terrain fencing, crash barriers and industrial buildings.

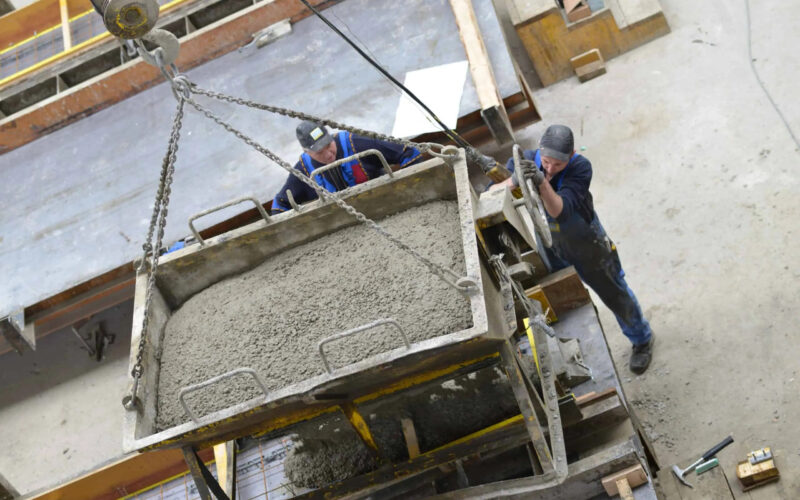

Using professional moulds you can create perfectly shaped large modular building blocks. Wet residual concrete is poured into the moulds to create a modular and easy-to-process building system. The moulds themselves are also modular, making it easy to produce blocks with different shapes and sizes. Modular moulds to create a modular construction system.

In larger quantities, the stackable concrete blocks can be joined together to build complete concrete structures. This construction system has the great advantage that structures can be easily placed, modified or dismantled. It is a matter of placing the structure, adjusting it if necessary, and eventually removing and reusing it.

So, residual concrete created in the production of precast concrete units can be used in an optimal circular concrete solution. We also call this upcycling residual concrete. The durable material that lasts forever can also be easily reused without first having to go through an energy-guzzling recycling process to produce new concrete.

Concrete slabs of various thicknesses can be used as site paving. An ideal way to pave agricultural or industrial sites. The surface of the site paving can be easily adjusted by effortlessly removing or adding concrete slabs.

By using dimensionally stable moulds, concrete plants show that they are committed to sustainability and circularity. They produce materials with low environmental impact and reduce waste streams generated by concrete production:

- All available leftover ready-mix concrete in the concrete plant is immediately put to beneficial use;

- It minimises the environmental impact of residual concrete and recycling processes;

- It creates products that have a long cycle of use;

- It creates circular products that can be used again and again without degrading in quality;

- It creates the possibility to use products for several applications.